Apparatus for Holding Yarn-Skeins (Julia Terry Hammonds, No. 572,985)

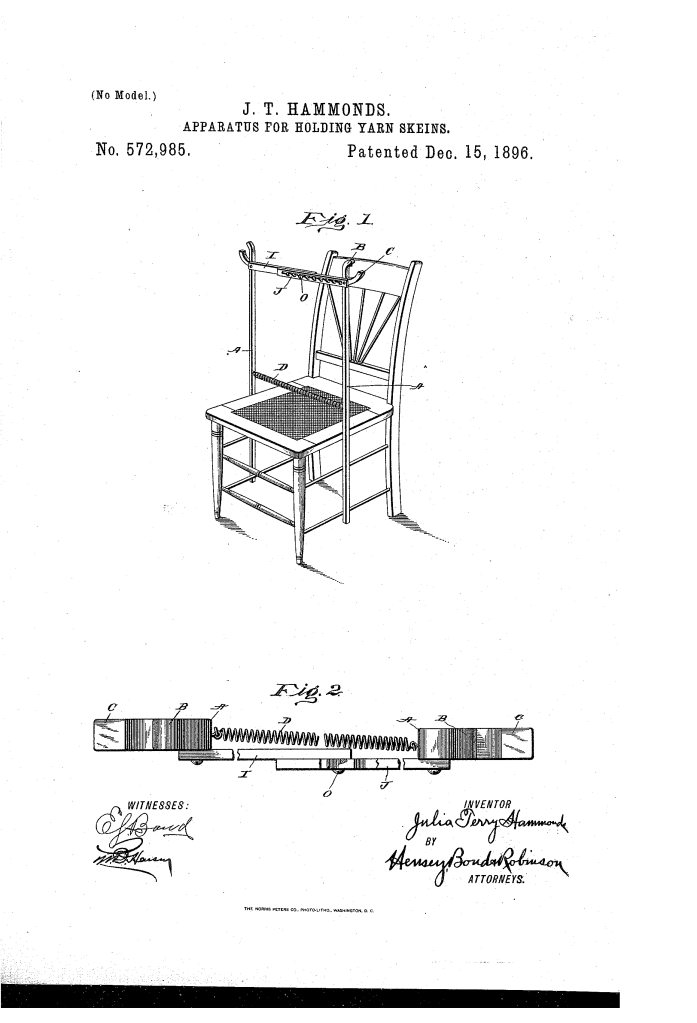

The patent by Julia Terry Hammonds of Lebanon, Illinois, describes an apparatus for holding yarn, silk, zephyr, and other material skeins (or hanks) while they are being wound. The objective is to provide a cheap and simple, hands-free means for winding material that is adjustable to the length of the skein and easily attachable to a chair or other support.

Invention and Mechanism

The apparatus is a portable, adjustable frame that clamps onto a chair and holds the yarn skein taut.

- Main Support and Clamping:

- Uprights (A): Two vertical arms of suitable length.

- Spring (D): A spring connecting the two uprights (A) below their upper ends.

- Function: The spring pulls the two uprights toward each other with enough force to hold them in upright contact against the opposite sides of a chair or other support. The spring automatically adjusts to the width of the chair.

- Vertical Adjustment: Since the spring is placed a considerable distance above the bottom, the apparatus can be adjusted vertically on the chair to the height most convenient for the user.

- Skein Holder:

- Pronged Upper Ends: The top of each upright (A) is pronged or forked to receive and hold the skein.

- Design: Each end consists of an outwardly-curved end (B) and an upwardly-curved arm (C).

- Function: The outward curve (B) prevents the skein from slipping off, and the upward curve (C) serves as a support to prevent the material from dropping or slipping down from its own weight.

- Adjustable Brace (Skein Length Adjustment):

- Brace Parts (I and J): A two-part brace is pivotally secured to each upright (A).

- Part I: A solid part carrying a headed stud or projection (O).

- Part J: Has a slot with a series of notches in its lower edge, designed to receive and lock the headed stud (O).

- Function: This brace is critical for adjusting the length of the apparatus to match the size of the skein. Once the apparatus is clamped to the chair, the brace is extended so the stud (O) locks into the appropriate notch. This keeps the upper ends of the uprights rigidly positioned, preventing them from moving toward each other due to the spring’s tension or the material’s weight.

- Portability: When not in use, the braces (I, J) can be separated and turned down into line with the uprights, and the spring (D) can be released, allowing the two uprights to be separated for packing in a very small space.

Historical Significance and the Inventor

Julia Terry Hammonds’s 1896 patent is a prime example of an inventor addressing a common domestic inconvenience, thereby improving efficiency and comfort in household tasks.

- Domestic Efficiency: Winding yarn from a skein for knitting or crocheting traditionally required a helper to hold the skein or using the back of a chair, which often allowed the yarn to tangle. Hammonds’s device provided a dedicated, hands-free solution that made the task a simple solo activity.

- The Inventor (Julia Terry Hammonds): Hammonds contributed to the wave of late 19th-century inventors—including women inventors—who focused on practical, simple, and functional improvements for domestic life, enhancing efficiency in textile crafts and household tasks.

Core Concepts Utilized Today

The apparatus’s design principles—using tension for clamping and a slotted/notched system for adjustable length—are prevalent in modern mounting hardware and organizers.

- Spring-Tension Clamping: The core method of attaching the device using an elastic element (Spring D) to create clamping tension against opposing surfaces is used in modern:

- Tension Rods: Used for curtains or room dividers, though they work internally rather than externally.

- Clamp-on Holders: Various cup holders, camera mounts, or desk organizers that use spring tension or screw tension to grip the edges of a surface.

- Notched/Slotted Adjustable Bracing: The design of the brace with a headed stud (O) and a notched slot (J) to provide rigid, adjustable length is a classic mechanical solution found in:

- Tent and Canopy Poles: Where a spring pin locks into a series of holes to adjust length.

- Modular Racks: Many modern shelving units and assembly frames use slotted brackets and pins to allow for rapid, rigid adjustment of component distances.

- Collapsible Design: The ability of the support arms to be folded down and separated for compact storage is a necessity for modern portable organizers and exercise equipment.