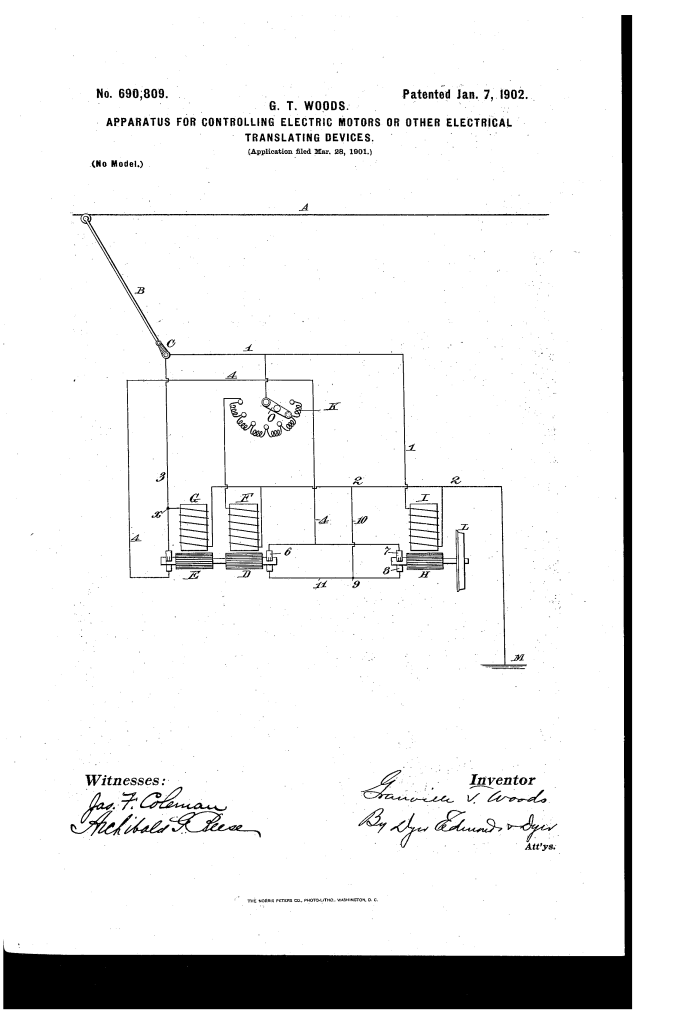

Apparatus for Controlling Electric Motors or other Electrical Translating Devices (Granville T. Woods, No. 690,809)

The patent by Granville T. Woods of New York, N.Y., describes a method and apparatus for Controlling Electric Motors (Patent No. 690,809, 1902). This invention is a refinement of his work on efficient motor control, aiming to dispense with resistive regulators (which waste energy as heat) and provide economic, precise speed regulation.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910), the “Black Edison,” was an exceptionally prolific African-American inventor specializing in electrical systems. This patent is a crucial piece of his advanced electrical engineering work, contributing to the development of efficient control systems for the expanding electric streetcar industry. His solution represents a leap forward in power management efficiency.

Invention and Mechanism (Simplified)

The system uses a constantly running “electro-converter” (dynamotor) to generate a secondary voltage that is injected into the main motor circuit, thereby precisely controlling the motor’s speed without burning off excess power as heat.

1. The Power Train (Series and Shunt)

- Working Motor (H): The main motor geared to the car axle.

- Auxiliary Motor (E): Runs constantly, taking power directly from the main power line (in “shunt,” or parallel).

- Generator (F): Mechanically driven by the auxiliary motor (E) on the same axis.

- Series Connection: The armature (H) of the working motor is connected in series with the armature (F) of the generator.

- Function: The auxiliary motor (E) runs the entire conversion system at a controlled speed. The generator (F) creates a controlled voltage that is added to the motor’s circuit.

2. Regulation by Magnetically Induced Voltage (Key Innovation)

- Counter Electromotive Force (EMF): The generator (F) produces a secondary voltage (EMF) which is injected into the circuit containing the working motor (H).

- Control: The output of the generator (F) is controlled by varying the current traversing its field coil (using a simple switch O K).

- Energy Efficiency: The method regulates the motor by varying the voltage that reaches it, rather than using resistance coils that simply absorb and waste energy as heat.

- Speed Control:

- Opposition: If the generator’s EMF opposes the main line voltage, the total voltage delivered to the motor (H) is reduced, slowing the car.

- Aiding: If the generator’s EMF aids the main line voltage, the total voltage is increased.

- Auxiliary Current: The generator (F) also feeds an auxiliary current to the main motor (H), supplementing the power from the main source.

Concepts Influenced by This Invention

Woods’s system established foundational principles for modern, efficient electric drive control and energy recovery.

- Non-Resistive Motor Control: The most significant influence is the move away from using resistive heat loss for speed control. This foundational principle is used in all modern Variable Frequency Drives (VFDs) and electronic motor control systems for large industrial motors, prioritizing energy efficiency and reducing waste.

- Dynamic Voltage Regulation: The core idea of using a rotating machine (Generator F) to inject a variable, controllable voltage into a primary circuit to regulate a motor’s speed influenced the design of sophisticated power control systems for elevators, industrial hoists, and cranes.

- Energy Management: The principle allows energy that might otherwise be wasted to be converted (through the generator F) and possibly recycled or used as an auxiliary current, establishing an early model for efficient energy management in transit.

- Dynamotor/Electro Converter: The use of a specialized machine (the dynamotor E/F) to convert and regulate power on-board the vehicle influenced the design of modern power converters and integrated auxiliary power units in electric vehicles and railway cars.