Alarm for Water-Containing Vessels (John O’Connor and Collatinus A. Turner, No. 598,572)

The patent by John O’Connor and Collatinus A. Turner describes an Alarm for Water-Containing Vessels (Patent No. 598,572, 1898). This is an improved safety device designed to give both electric and whistle warning when the water level in a vessel (such as a steam-boiler) rises or falls beyond certain desired levels, and to simultaneously control a water-supply valve.

Inventor Background: John O’Connor and Collatinus A. Turner

John O’Connor and Collatinus A. Turner were partners who specialized in safety and control mechanisms for steam technology. They previously invented an Alarm for Boilers (No. 566,612) and a Steam-Gage (No. 566,613). This patent represents the highest evolution of their system, integrating multiple alarms and remote valve control into a single, comprehensive safety unit. Their work was crucial for improving the safety of high-pressure steam power in the late 19th century.

Invention and Mechanism

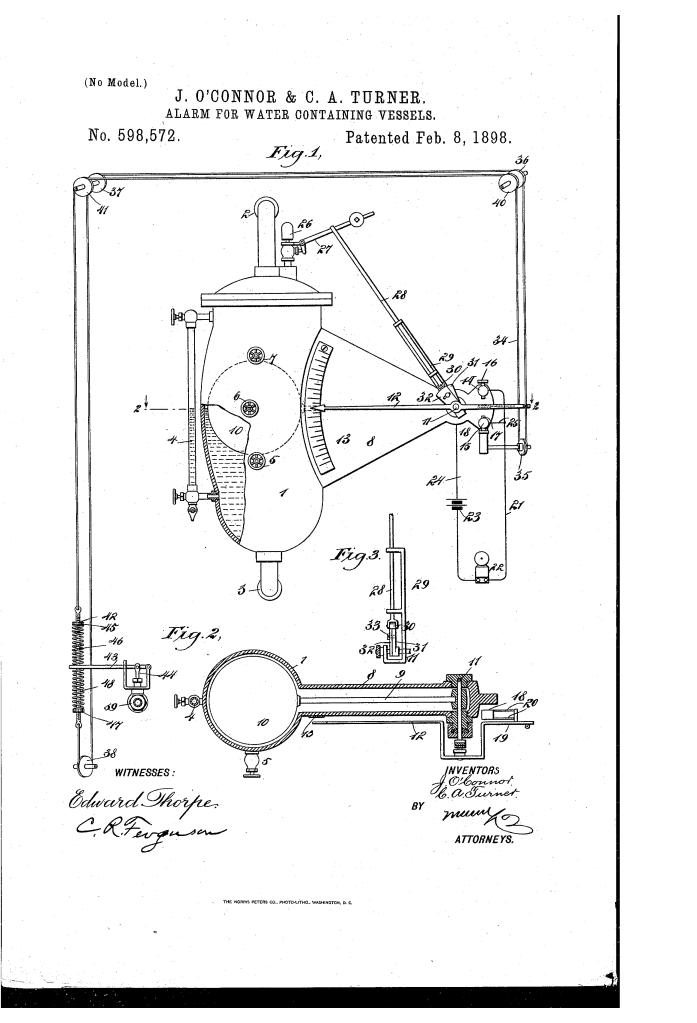

The alarm is a float-actuated mechanical and electrical control center that translates the vertical movement of the water level into three distinct output actions.

1. Float Sensor and Indicator

- Water Cylinder (1): A cylinder connected to the top and bottom of the main vessel (boiler), ensuring its water level (4) matches the boiler’s.

- Float (10) and Shaft (11): A float (10) operates in the cylinder (1) and is rigidly connected to a shaft (11) extended transversely through a casing (8).

- Indicator (12, 13): A pointer (12) on the shaft moves over a gage-plate (13), providing a visible, mechanical indicator of the water level that functions as a backup should the primary water gage fail.

2. Dual Alarm System (Electric and Whistle)

- Electric Alarm:

- Contacts: Adjustable contact-points (16, 17) are mounted on binding-posts.

- Actuation: A spring-yielding contact-plate (18), carried by the pointer arm (19), engages these points on high or low water, completing a circuit to a battery (23) and an electric bell (22). The yielding mount allows for slight over-travel while maintaining contact.

- Whistle Alarm (Steam-Actuated):

- Plates (31, 32): Adjustable plates are mounted on the shaft (11). These plates are moved by the float.

- Valve Lever (27): The movement of the plates (31, 32) displaces a roller (30) on a rod (28), which is connected to a lever (27) that opens the valve of a steam whistle (26).

- Function: When the plates move out of alignment with the roller (30), the whistle valve opens, sounding an audible steam alarm.

3. Remote Valve Control (Water Supply) (Key Innovation)

- Control Valve (39): A valve (e.g., controlling a water-pump or supply pipe).

- Rope Linkage (34): A rope or wire is connected to the pointer arm (19) and extends over a series of pulleys to the control valve (39).

- Yielding Connection (45, 46): The rope connects to the valve stem via a lever (43) and a rod (42) that has adjustable collars (45, 47) and springs (46), providing a yielding connection.

- Function: As the float moves up or down, it pulls the rope (34), which operates the valve lever (43). When the water is too low, the valve opens the pump (supply). When the water reaches the highest level, the float pulls the valve closed, cutting off the supply. The yielding spring connection ensures the alarm circuit remains closed even if the valve system momentarily sticks.

Concepts Influenced by This Invention

The system influenced subsequent safety and control mechanisms by pioneering a multi-functional, layered response to a single critical sensor input.

- Layered/Redundant Alarming: The use of two parallel, independent alarm types (electric bell and steam whistle) for the same event influenced the design of critical safety systems requiring redundancy to ensure the warning is received, especially across industrial noise.

- Simultaneous Transduction of Output: The system’s ability to translate the single vertical input (float movement) into three concurrent outputs—visual indicator, electrical circuit change, and pneumatic/steam valve action—is a fundamental principle in modern industrial control and process monitoring systems.

- Yielding Control Actuation: The use of springs (46) and adjustable abutments (45, 47) in the valve control linkage influenced the design of actuators that require a safety buffer. The yielding connection ensures that the sensor (float) can continue its movement to fully activate the alarm, even if the primary control target (valve 39) encounters unexpected mechanical resistance.

- Mechanical-to-Electrical-to-Pneumatic/Hydraulic Conversion: The invention is a robust historical example of converting a simple mechanical measurement (float level) into both an electrical signal and a fluid control action, which is the definition of a comprehensive integrated safety loop.