Alarm for Boilers (John O’Connor and Collatinus A. Turner, No. 566,612)

The patent by John O’Connor and Collatinus A. Turner describes an Alarm for Boilers (Patent No. 566,612, 1896). The invention provides a simple and inexpensive device to give electric warning when the water level in a steam boiler rises above or falls below a certain predetermined level.

Invention and Mechanism

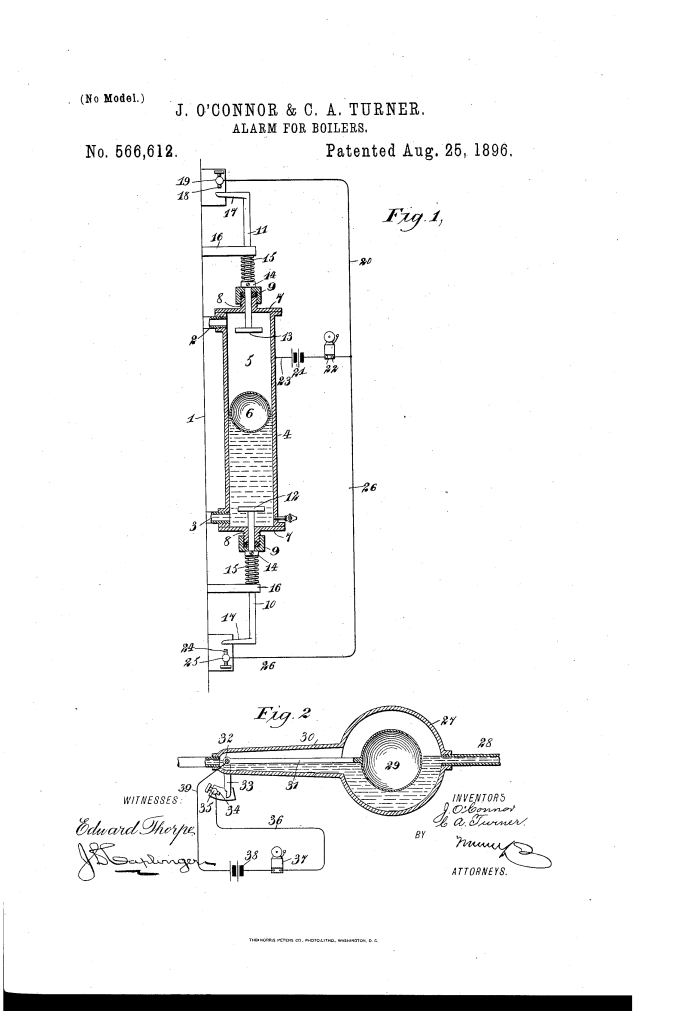

The alarm is a float-actuated electrical switch system housed in an external chamber connected to the boiler.

1. Float and Chamber

- Float Chamber (4): A vertically arranged cylinder connected to the boiler (1) via pipes (2 and 3) above and below the normal water level. The chamber’s interior (5) fills with water and steam, allowing the water level inside to match the boiler’s level.

- Ball Float (6): A ball float inside the chamber (4) rises and falls with the water level.

2. Upper and Lower Alarm Stems (Switches)

- Stems (10 and 11): Two rods extending through the upper and lower heads (7) of the chamber (4) via stuffing-boxes (9). Their inner ends have enlargements (12, 13) positioned to be engaged by the float (6).

- Spring Retention: Springs (15) coiled upon the stems bear against adjustable collars (14), holding the stems with their heads pressed inward, ready to be moved by the float.

- Adjustment: The adjustable collars (14) allow the stems to be moved longitudinally, setting the precise high and low water levels at which the alarm will sound.

3. Electric Circuit and Stop Function (Key Innovation)

- Contacts (18 and 24): Adjustable screws mounted in fixed posts (19, 25).

- Alarm Circuit: The stems (10, 11) have outer lateral arms (17). The circuit includes a battery (21), a bell (22), and wires connecting the boiler/stem (one terminal) to the contact screws (the other terminal).

- Operation (High/Low Alarm):

- Low Water: The float falls, pulling stem (10) outward. Arm (17) engages screw (24), closing the circuit and ringing the bell.

- High Water: The float rises, pushing stem (11) outward. Arm (17) engages screw (18), closing the circuit and ringing the bell.

- Stop Function: The screws (18 and 24) are positioned to act as stops to prevent further movement of the arms (17). This ensures the circuit remains held closed and the bell continues to ring as long as the water level remains outside the set limits, preventing the arm from moving past the screw and reopening the circuit.

Historical Significance and the Inventors

The 1896 patent addresses a fundamental safety requirement for steam power, which was vital for both industrial machinery and transportation (locomotives, ships).

- Boiler Safety: In the late 19th century, boiler explosions due to dangerously low water levels (causing overheating) or dangerously high water levels (causing water carryover into the engine) were serious, potentially catastrophic industrial hazards. The alarm provided an essential, reliable warning system.

- Electric Alarm Integration: The invention’s significance lies in its use of electricity to sound the alarm. An electric bell could be located remotely, was loud, and offered a reliable mechanism to hold the circuit closed, improving upon simple mechanical whistles or weighted indicators.

- Adjustability: The provision for adjusting the set points (via collars 14) made the device versatile, allowing it to be adapted for different types and sizes of boilers with varying operating parameters.

- The Inventors: John O’Connor and Collatinus A. Turner contributed to the necessary safety infrastructure of the steam-powered era.

Concepts Influenced by This Invention

The alarm system influenced subsequent sensor and control mechanisms by pioneering a float-actuated electrical interlock with a sustained alarm function.

- Float-Actuated Sensing: The fundamental principle of using a float and an external chamber to sense liquid level and translate that movement into a mechanical action is the basis for most modern fluid level sensors, including those used in fuel tanks, sump pumps, and industrial process tanks.

- Sustained Alarm Interlocks: The design where the contact screw acts as a mechanical stop to keep the circuit closed (sustaining the alarm) influenced the design of industrial safety sensors. Modern safety interlocks often use latching relays or contacts that remain engaged until the dangerous condition is explicitly resolved, functionally equivalent to O’Connor and Turner’s mechanical stop.

- Adjustable Set Points: The ability to easily and precisely adjust the trip point (via collars 14) influenced the design of all modern industrial sensors, which feature accessible calibration points for setting high and low limits.

- Mechanical-to-Electrical Transduction: The system is an excellent example of transducing a continuous mechanical state (water level) into a discrete electrical signal (alarm ON/OFF), a core concept in control engineering.