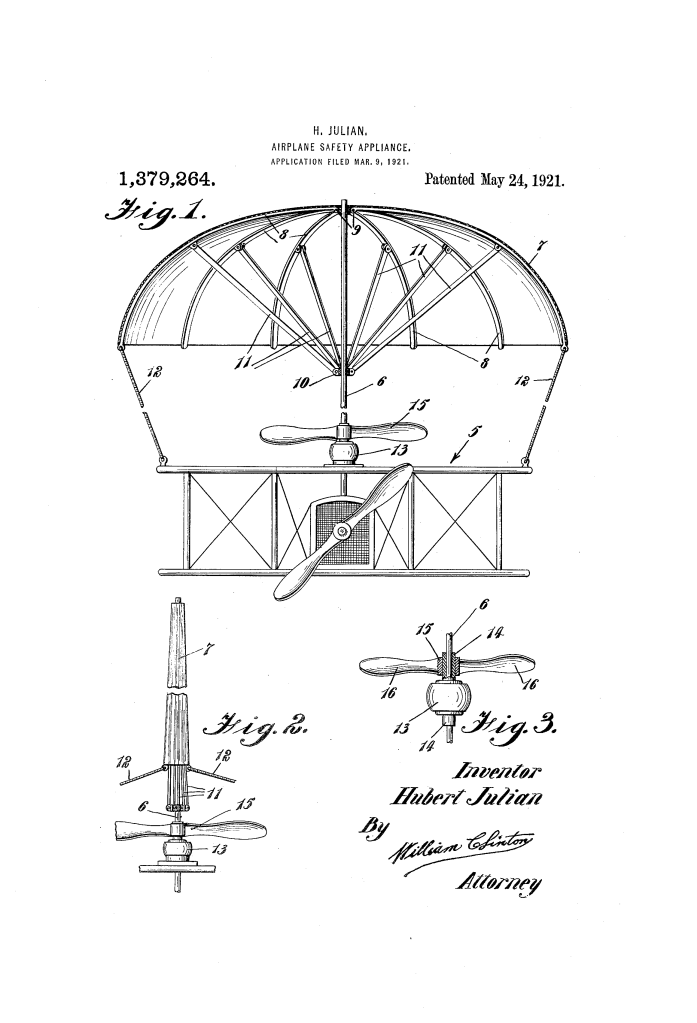

Airplane Safety Appliance (Hubert Julian, No. 1,379,264)

The patent by Hubert Julian of Montreal, Quebec, Canada, describes an Airplane Safety Appliance (Patent No. 1,379,264, 1921). This invention is a specialized emergency system designed to prevent aircraft from crashing in the event of engine failure. Julian’s primary innovation was the integration of a collapsible parachute mounted directly to the airplane’s frame, which could be mechanically deployed and held open by an independent motor-driven fan. This system aimed to provide a controlled, gradual descent, protecting both the machine and its occupants from the high-velocity impact of a fall.

Inventor Background: Hubert Julian

Hubert Julian (1897–1983), known as “The Black Eagle,” was a pioneering Trinidadian-born aviation ace and one of the most colorful figures in early 20th-century flight. Julian was a master of self-promotion and a world-renowned parachutist, famously performing stunts over New York City. His 1921 patent reflects his deep practical knowledge of parachute mechanics and his concern for the inherent dangers of early “sticks and wires” biplanes. Julian’s design was forward-thinking, anticipating the ballistic parachute systems used in modern light aircraft (such as Cirrus) by nearly 80 years.

Key Mechanical Components & Functions

The safety appliance is a structural attachment that sits above the central axis of the airplane.

1. The Vertical Shaft and Parachute (6, 7)

- The Mast: A vertical shaft (6) extends upward from the center of the airplane, passing through the upper wing.

- The Ribs and Stays (8, 11): The parachute (7) is built like a sturdy umbrella, with ribs (8) pivoted to the top of the shaft (9) and connected to a sliding ring (10) by stays (11).

- Function: In its normal state, the ring sits at the bottom of the shaft, and the parachute is collapsed (Fig. 2) to reduce drag during flight.

2. The Independent Motor and Fan (13, 15) (Key Innovation)

Standard parachutes rely on the wind of a fall to open. Julian’s system uses active mechanical force.

- Independent Motor (13): An electric motor, powered by a storage battery, is mounted at the base of the shaft.

- The Propeller Fan (15): The motor drives a sleeve (14) that rotates around the shaft, spinning a large fan (15) with blades (16) located directly beneath the parachute.

3. Active Deployment and Air Cushioning

- Deployment: In an emergency, the pilot activates the motor. The fan spins rapidly, creating an upward blast of air.

- Action: This air pressure catches the underside of the parachute, forcing the ribs outward and sliding the ring (10) up the shaft into the fully extended “operative” position (Fig. 1).

- Descent Control: Once open, the fan continues to drive air against the parachute canopy. This creates a “buoyancy” effect that allows the machine to settle toward the ground at a safe, controlled speed.

4. Flexible Stabilizing Cables (12)

- Tethering: To prevent the parachute from swaying or tearing away under the pressure of the fan and the fall, flexible cables (12) connect the ends of the ribs directly to the main body of the airplane.

Improvements Over Existing Safety Methods

| Feature | Standard 1920s Emergency Options | Julian’s Safety Appliance |

| Deployment | Required pilot to jump or manual chute release. | Mechanically deployed via motor and fan. |

| Reliability | Chutes often failed to open at low altitudes. | Fan creates immediate internal pressure to open the chute. |

| Machine Protection | Pilot survived, but the airplane was destroyed. | Designed to save both the occupants and the aircraft. |

| Control | No control over descent speed. | Fan speed can be regulated to control the rate of descent. |

Significance to Aeronautical Engineering

Hubert Julian’s safety appliance influenced the development of emergency recovery systems and aerodynamic braking.

- Active Inflation: Julian recognized that “passive” inflation (depending on the speed of the fall) was the weak point of parachutes. His “active” inflation concept via a fan is an early precursor to pyrotechnic and ballistic deployment systems used today.

- Integrated Airframe Systems: By treating the parachute as a permanent part of the airplane’s structure rather than a piece of personal gear, Julian helped pioneer the concept of Whole-Airframe Recovery Systems (CAPS).

- Independent Power Source: The requirement for an independent motor (separate from the main engine) is a core safety principle in modern engineering, ensuring that critical safety gear works even if the primary power plant fails.

- Vertical Lift Theory: The logic of using a fan to create an upward air cushion under a canopy overlaps with the early principles of hovercraft and VTOL (Vertical Take-Off and Landing) technology.