Cornice (Samuel R. Scottron, No. 270,851)

The patent by Samuel R. Scottron of Brooklyn, New York, describes an Improvement in Cornices (Patent No. 270,851, 1883). The invention focuses on providing a durable and easily transportable extensible window cornice that can be securely fastened to the window frame or wall.

Inventor Background: Samuel R. Scottron

Samuel R. Scottron (1843–1908) was a prominent African-American inventor, businessman, and civic leader.1 His inventions, including this cornice, an adjustable mirror, and a supporting bracket, addressed improvements in domestic utility and aesthetics. His focus was on creating practical, high-quality, and reliable products for the home.

Invention and Mechanism (Simplified)

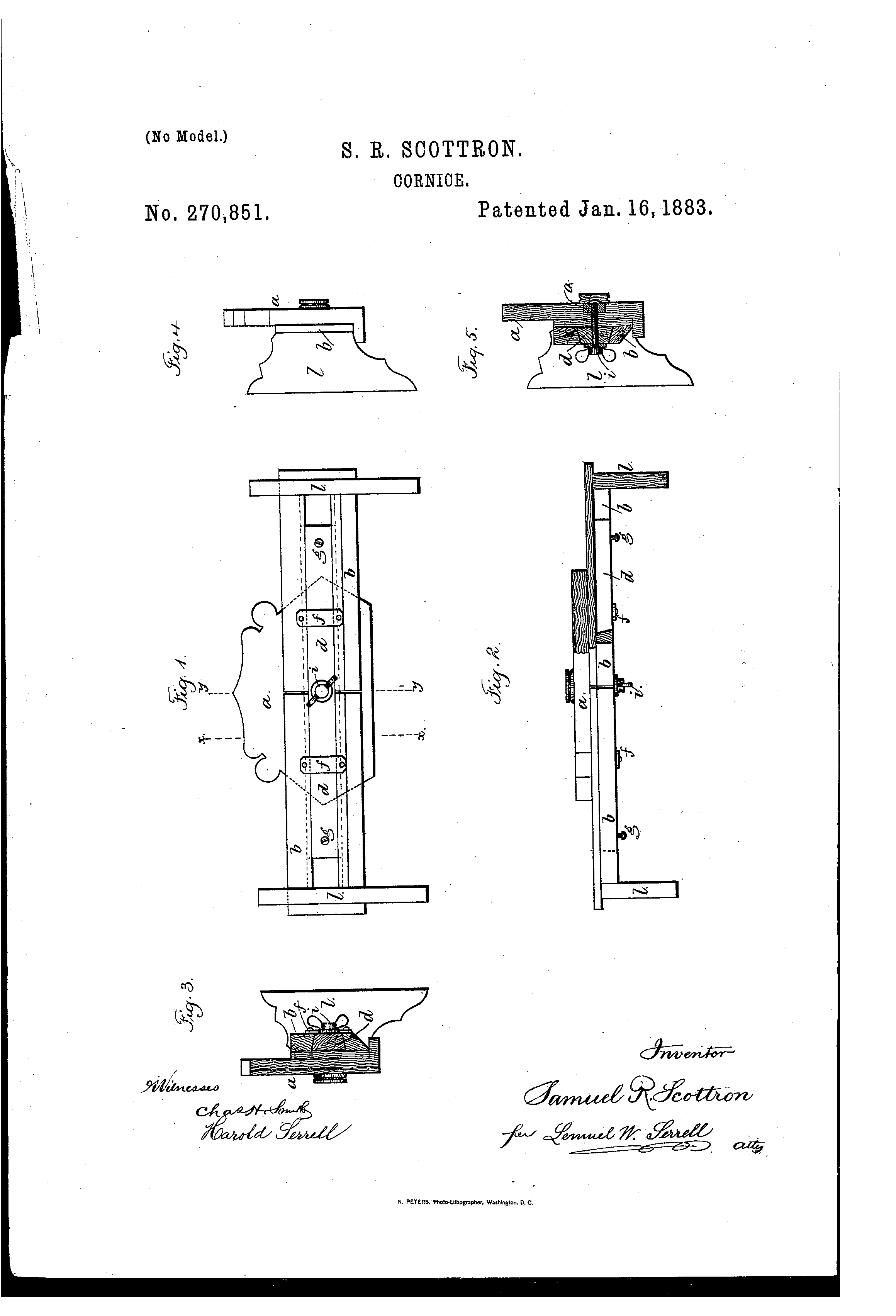

The cornice is a three-part assembly that slides to adjust its width and locks rigidly using a hidden, removable screw and nut system.

- Extensible Body:

- Central Part (a): The main ornamental body of the cornice.

- Extension Sections ($b, b$): Two sections located behind the ornamental part.

- Back Bar ($d$): This bar slides between the central part and the extension sections.

- Sliding and Guidance: The edges of the back bar ($d$) and the extension sections ($b, b$) are made with tongues and grooves or dovetails.

- Function: This interlock ensures the parts slide smoothly and are held against lateral movement. Cross-plates ($f$) are fastened to the extension sections to keep the back bar captured within the grooves.

- Secure Clamping (Key Innovation):

- Clamping Screw ($i$): A screw passes from the back through the back bar ($d$).

- Nut ($c$): A special nut is secured into the front portion of the central part ($a$) of the cornice.

- Function (Locking): The screw ($i$) threads into the nut ($c$), firmly clamping the extension sections ($b, b$) against the central part ($a$), locking the cornice at the desired width.

- Transport and Safety:

- Removable Screw: When the cornice is disassembled for transportation, the screw ($i$) is entirely removed. This prevents the screw from projecting and being broken off or injuring the cornice parts during packing, which was a major flaw in older designs.

- Brackets and Stability:Brackets ($l, l$) are fastened permanently to the extension sections ($b, b$).

- Function: By combining adjustable width with fixed, sturdy end brackets, the cornice can be sized to fit any window and then screwed directly to the window-frame or wall for a very firm and reliable installation.

Concepts Influenced by This Invention

Scottron’s extensible cornice influenced subsequent modular and adjustable furniture and hardware by pioneering internal, easily disassembled locking systems for decorative components.

- Internal, Removable Locking: The most significant influence is the concept of a clamping screw that passes through the rear component to engage a fixed nut in the front component, allowing the screw to be completely removed for transport. This influenced the design of:

- Flat-Pack Furniture: Assembly methods where cam-locks or locking screws are easily inserted and removed, minimizing projecting hardware during shipping.

- Adjustable Rods and Frames: Systems that lock an extension piece rigidly but allow the primary fastener to be fully withdrawn.

- Tongue-and-Groove Guidance: The use of dovetails or tongues and grooves to guide the sliding movement and prevent lateral shifting influenced the design of numerous adjustable drawer slides, modular cabinet systems, and extensible hardware.

- Integrated Universal Mounting: Combining the extensible frame with fixed, structural end brackets influenced the design of modern adjustable-width consumer hardware (like curtain rods or closet organizers) that require a stable mounting point at the point of maximum extension.