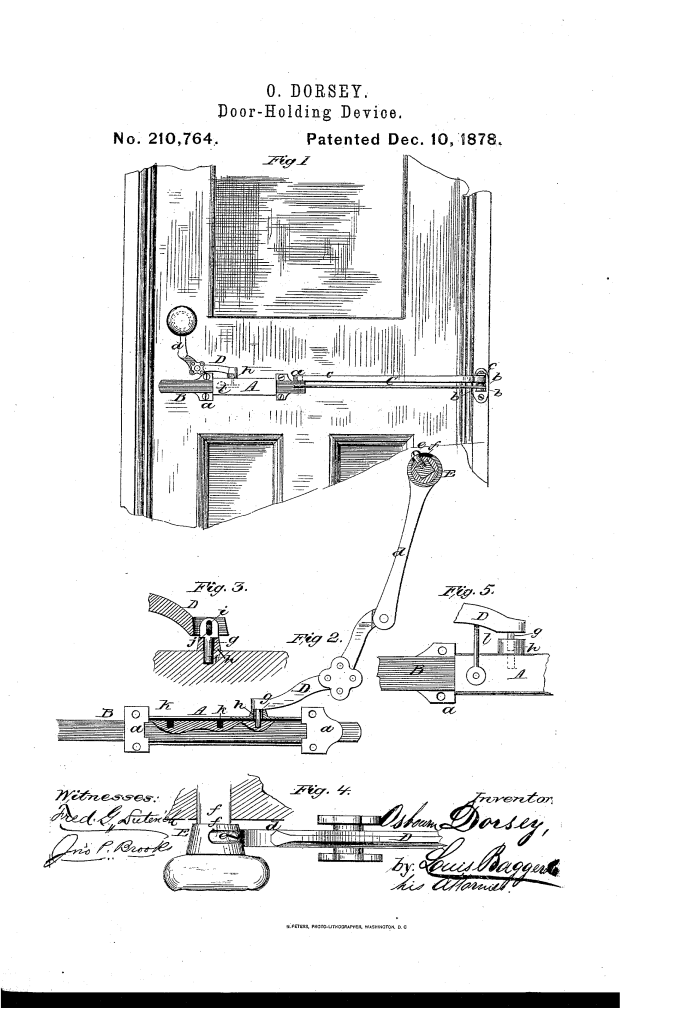

Improvement in Door-Holding Devices (Osbourn Dorsey, No. 210,764)

The patent by Osbourn Dorsey of Washington, D.C., describes an Improvement in Door-Holding Devices (Patent No. 210,764, 1878). The invention is a complex mechanism designed to secure a door open at any desired angle and prevent its accidental slamming due to drafts, while being easily released by turning the doorknob.

Invention and Mechanism

The device is an integrated mechanical system that links the door’s movement and latch mechanism to a separate locking rod.

1. Door Holding Mechanism

- Slide or Bar (B): A bar that slides through a case (A) secured to the door. This bar has a series of notches () along its length.

- Rod (C): Connected to the rear of the slide (B) and hinged/pivoted to the door-frame (or casing).

- Closing Spring: A coiled spring (

) around the rod’s axis automatically tries to close the door when the bar (B) is free to slide.

- Closing Spring: A coiled spring (

- Locking Pin (): A pin carried by the operating lever (D).

- Function: When the door is opened to a desired angle, the pin (

) falls by gravity into a coincident notch (

) in the slide (B), locking the door in a fixed position against the tension of the closing spring (

).

- Function: When the door is opened to a desired angle, the pin (

2. Knob-Actuated Release (Key Innovation)

- Bell-Crank Lever (D): Pivoted to the door. One end carries the locking pin (

).

- Sleeve/Collar (E): A collar placed on the knob-spindle, connected to the other end of the lever (D) by an arm (

).

- Slotted Connection: The knob-spindle has a projection (

) (e.g., a screw-bolt) that enters a slot () in the collar (E).

- Function: The slot (

) allows the knob to be turned far enough to withdraw the latch-bolt without immediately affecting the holding device. However, a reverse movement of the knob (turning it back, or a slight turn beyond the latch position) elevates the pin () of the lever (D), disengaging it from the notch in the slide (B) and releasing the door.

- Function: The slot (

3. Operation (Locking/Unlocking)

- Locking: The user turns the knob to open the door, then releases the knob. The pin (

) automatically falls into a notch (

), securing the door.

- Unlocking: The user turns the knob (or gives a reverse turn) to lift the pin (

), which allows the door to be automatically closed by the spring (

).

4. Auxiliary Features

- Propping-Lever (): Pivoted to the case (A), this lever props the pin (

) in an elevated position, preventing it from engaging the slide when the holding device is not needed.

Historical Significance and the Inventor

Osbourn Dorsey’s 1878 patent is an important example of an inventor integrating security, convenience, and safety into a single, complex hardware solution.

- Safety and Convenience: The invention directly addressed the common problem of doors being slammed by drafts, a risk factor for doors with glass (common in offices and inner hallway doors). By automatically securing the door and providing a convenient release via the knob, it enhanced both safety and user experience.

- The Interlock Mechanism: The key significance is the use of the doorknob/latch function as the release mechanism for a separate door-holding mechanism. This mechanical interlock simplifies the operation—the user doesn’t need a separate lever or button to release the hold, only the existing knob.

- The Inventor (Osbourn Dorsey): Osbourn Dorsey is an African-American inventor who contributed a highly specialized and ingenious solution to the field of architectural hardware. His work demonstrates complex mechanical problem-solving applied to domestic and commercial utility.

Concepts Influenced by This Invention

Dorsey’s invention influenced subsequent hardware design by pioneering an effective knob-actuated mechanical interlock for a secondary function.

- Knob/Actuator Interlocks: The concept of using the rotation of a primary control element (the knob spindle) to mechanically actuate a separate, secondary mechanism (the door lock/hold) is a principle used in modern:

- Safety Locks on Appliances: Mechanisms that require a specific twist of a handle or knob to engage a safety feature.

- Push-Button Latches: Systems where the twisting action of a door handle releases a secondary catch.

- Notched/Sliding Position Locks: The use of a notched bar (B) and a gravity-actuated pin () to lock a component at multiple, discrete positions is a classic mechanical solution found in adjustable tables, steering columns, and ratchet-and-pawl systems where position must be rigidly maintained.

- Remote Release of Safety Mechanism: The ability to release the door hold without touching the securing mechanism itself, merely by turning the knob, influenced the design of remote-release safety catches and latches in both furniture and machinery.

- Prop-Mechanism for Disengagement: The auxiliary lever (

) to lift and prop the pin out of the way influenced the design of selectively engaging hardware where a component (like a spring-bolt or catch) needs to be physically disengaged and stored when its function is not required.