Improvement in Furniture-Casters (David A. Fisher, Jr., No. 174,794)

The patent by David A. Fisher, Jr., of Washington, D.C., describes an Improvement in Casters for Furniture (Patent No. 174,794, 1876). The main object is to create a caster where the wheel and spindle will not fall out from its socket as easily as ordinary casters, and to provide a socket that can be installed without a wrench.1

Invention and Mechanism

The improvement involves a self-retaining, spring-action spindle and a socket designed for easier installation.

- Self-Retaining Spring Spindle (Key Innovation):

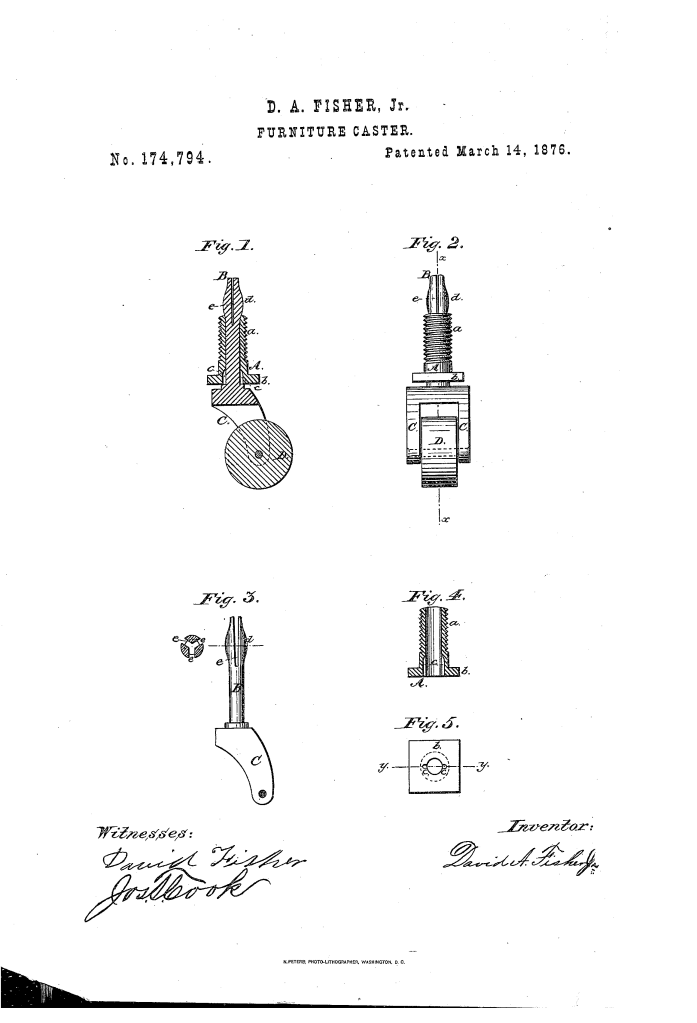

- Spindle (B) and Frame (C): The shank or spindle (B) is attached to the caster frame (C), which holds the roller (D).

- Split and Enlarged End: The upper end of the spindle (B) is enlarged () and split (e.g., into two or more parts,

). Being made of steel or similar material, these split ends form a spring.

- Function: When the spindle is forced into its socket (A), the split, enlarged parts are compressed. The resulting spring-action and frictional contact securely hold the spindle in place, preventing it from dropping out when the furniture is lifted or moved.

- Improved Socket/Thimble (A):

- Screw Thread (): The socket (A) is threaded for insertion into the foot of the furniture.

- Installation Aid: The lower inner side of the socket (A) is provided with grooves or transverse slots ().

- Function: These slots allow the end of a screwdriver or other suitable tool to be inserted, enabling the socket to be screwed into place easily. This is an alternative to using a wrench applied to the external flange (

).

- Operation Principle: The socket (A) is first screwed into the furniture leg. The spring-spindle (B) is then inserted and forced into place. The compression and expansion of the split end securely and quickly attaches the caster, providing a solution to the common problem of casters dropping out when furniture is lifted.2

Historical Significance and the Inventor

- The Problem of Loose Casters: The invention addressed a ubiquitous domestic annoyance. Early furniture casters often relied solely on gravity and a loose fit, causing them to detach easily when the furniture was moved. This made moving heavy items awkward and could damage the caster or the floor.

- The Spring-Lock Concept: Fisher’s use of a spring-action, compressed-fit connection was an important mechanical refinement. It transitioned the caster from a loose, gravity-held component to a secure, retained component.

- The Inventor (David A. Fisher, Jr.): Fisher, residing in Washington, D.C., was also the inventor of the adjustable joiner’s clamp. His work demonstrates a consistent focus on practical mechanical improvements for carpentry, furniture, and domestic utility.

Core Concepts Utilized Today

Fisher’s caster design employs principles that are essential to modern snap-fit and friction-lock hardware.

- Spring-Retention Fasteners (Snap-Fit): The design uses the elasticity of the material (the split spindle) to create a quick-insert, high-retention lock when compressed into the socket. This is the core principle of modern snap-fit connectors, retaining clips, and push-in fasteners used in automotive, consumer electronics, and furniture assembly.

- Friction-Lock Casters: While sophisticated ball-bearing casters are now common, the basic design of many utility and office chair casters still relies on a friction grip, often via a split stem or retention ring, to securely hold the wheel assembly in the chair base.

- Tool Interface Grooves: The slots on the socket for screwdriver insertion are an early example of providing a simple, accessible interface for a common tool. This is standard in modern hardware, where manufacturers add driver slots or holes to components (like anchor sleeves or pipe fittings) to simplify installation without requiring specialized tools.