The patent by Alexander P. Ashbourne of Oakland, California, describes a novel and improved Process for the Preparation of Cocoa-Nut for Domestic Use (Patent No. 163,962, 1875). The objective is to prepare coconut meat so that it will “keep fresh many years” and retain its flavor, making it suitable for long-term packing and domestic use.

Invention and Mechanism

The invention details a thermal and chemical process for stabilizing and preserving the coconut meat:

- Preparation and Sifting: The nuts are pared (peeled), and the meat is grated or otherwise pulverized. It is then passed through fine screens or sieves, with hot boiling water being added at the same time.

- Cooking: The meat is subjected to hot steam for three or four hours until it is thoroughly cooked.

- Pressing and Drying: The cooked meat should then be pressed perfectly dry and subsequently dried gradually until it is fit for packing.

- Curing (Sweetening and Flavoring): After cooking and before drying, the following ingredients are mixed in:

- White sugar: In the proportion of one pound of sugar to three pounds of meat.

- Fine stick cinnamon: A small quantity is added to preserve the flavor.

- Result: The process involves cooking, drying, and treating the meat with sugar and cinnamon. The combination is claimed to make the product keep and retain its flavor for years without depreciation.

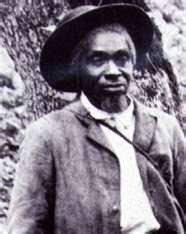

Historical Significance and the Author

- The Inventor (Alexander P. Ashbourne): This is one of the earliest known U.S. patents granted to Alexander P. Ashbourne, an African-American inventor. His focus on commodity processing (coconut) and domestic utility (biscuit cutter) highlights his innovative approach to solving practical problems in food preparation and manufacturing during the 1870s.

- Food Preservation: The invention is significant in the history of food technology, specifically addressing the critical problem of preserving tropical food products for long-distance transport and storage. Coconut meat, being high in moisture and oil, spoils quickly. Ashbourne’s process used heat (steam cooking), dehydration (pressing and drying), and sugar (a preservative)—the core methods of industrial food preservation.

- Standardizing Domestic Ingredients: By creating a process for a stable, long-lasting form of coconut meat, the invention contributed to making the ingredient a standardized, year-round staple for domestic cooking, far removed from its place of origin.

Core Concepts Utilized Today

Ashbourne’s process uses fundamental, time-tested food science techniques that are still core to modern food processing and preparation.

- Drying and Dehydration: The process of pressing and gradually drying the coconut meat to reduce moisture content is the foundational technique for modern dehydrated fruit and vegetable products , extending shelf life dramatically by inhibiting microbial growth.

- Osmotic Preservation (Sugaring): The use of high concentrations of sugar (one part sugar to three parts meat) to draw out moisture and act as a natural preservative is known as osmotic dehydration. This principle is widely used today in canning, jams, and candied fruits, where sugar lowers the water activity to prevent spoilage.

- Thermal Processing (Steam Cooking): Subjecting the meat to steam heat serves to both tenderize the product and eliminate microbes and enzymes that cause spoilage, a process now known as blanching or pasteurization. This is a standard initial step in preparing many packaged foods.

- Aroma Stabilization: The use of cinnamon to “preserve the flavor” points to the use of spices or essential oils as natural flavor stabilizers and antioxidants, a practice common in modern food formulation.