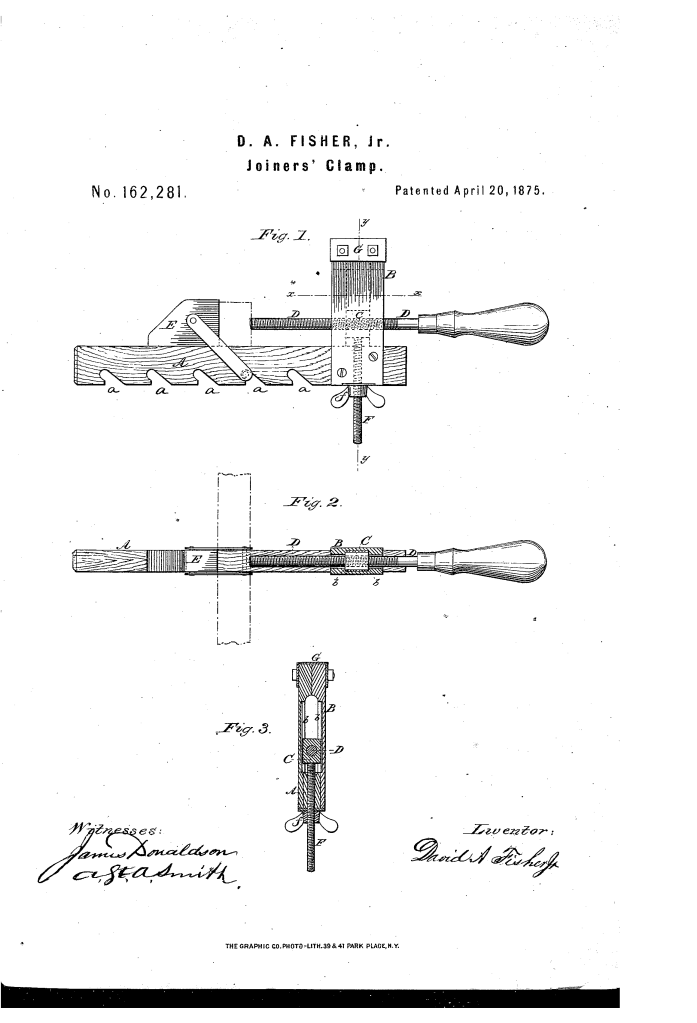

Improvement in Joiners’ Clamps (David A. Fisher, Jr., No. 162,281)

The patent by David A. Fisher, Jr., of Washington, D.C., describes an Improvement in Joiners’ Clamps. The object of the invention is to provide a mechanism that allows the user to easily and readily adjust the nut that holds the clamping screw, ensuring the clamping force is applied to the central part of the wood regardless of the wood’s thickness.

Invention and Mechanism

The invention adds a lateral, secondary screw mechanism to the main clamping body to control the position of the clamping nut.

- Main Clamp Structure:

- Bed (A): The main body of the clamping device, typically a bar with notches (

).

- Support (B): A screw block secured to one end of the bed (A). This block houses the improved mechanism.

- Clamping/Pressure Screw (D) and Block (E): The main screw that applies pressure, fitted with a standard pressure block (E) at the opposite end.

- Bed (A): The main body of the clamping device, typically a bar with notches (

- Adjustable Nut System (Key Innovation):

- Nut (C): The main nut into which the clamping screw (D) is fitted. This nut is designed to be adjustable in position.

- Guideways (b): The nut (C) slides laterally within guideways (b) located inside the support block (B). These guides are preferably lined with metal to prevent wear.

- Regulating-Screw (F): A screw connected to the nut (C) that operates at a right angle to the main clamping screw (D).

- Thumb-Nut (): A nut on the regulating-screw (F) used to hold the adjustable nut (C) in the desired lateral position.

- Operation Principle:

- Adjustment: Once wood of any thickness is placed against the block (E), the user turns the regulating-screw (F). This action slides the main nut (C) laterally within the support block (B).

- Central Purchase: The user adjusts the nut (C) until it is aligned with the central part of the wood. The regulating-screw (F) is then locked with the thumb-nut (

).

- Clamping: The main clamping screw (D) is then tightened, ensuring the applied force is central to the workpiece, regardless of thickness.

Historical Significance and the Inventor

David A. Fisher, Jr.’s 1875 patent is a specialized refinement of a fundamental tool used in the carpentry and cabinet-making trades.

- Trade Tool Precision: The joiner’s clamp is essential for gluing and holding wood pieces. The problem addressed is common: when clamping wood of varying thicknesses, the force from the screw often hits the workpiece off-center. This can cause the wood to twist, bow, or slip, ruining the joint.

- Mechanical Solution for Alignment: Fisher’s solution of adding a secondary, perpendicular screw-drive to position the primary nut was an elegant mechanical answer to achieve precision and uniform stress distribution. It eliminated the need for shims or manual adjustments to the workpiece.

- The Inventor (David A. Fisher, Jr.): Fisher, residing in Washington, D.C., contributed a practical innovation to the woodworking trades, demonstrating a focus on improving the accuracy and efficiency of essential hand tools.

Core Concepts Utilized Today

Fisher’s clamp utilizes mechanical concepts that are essential in precision fixturing, tooling, and linear motion control.

- Linear Adjustment of Load Components: The use of a secondary screw (F) to precisely and rigidly position a primary load-bearing component (Nut C) along a linear path (Guideways b) is the core principle of machine slides, lead screw assemblies, and CNC machine axes . This design ensures precise alignment of force or motion.

- Centralizing Fixtures: The principle of achieving a “central purchase” (self-centering force) regardless of workpiece dimensions is a primary goal of modern self-centering vises and chucks used in machining and manufacturing. Fisher’s manual lateral adjustment achieves a similar result.

- Adjustable Tooling Jigs: The mechanism acts as a simple, rigid jig to ensure the clamping pressure is always perpendicular and centered on the joint. This concept is fundamental to specialized welding clamps, assembly jigs, and custom tooling fixtures where the force application point must be variable but precisely controlled.