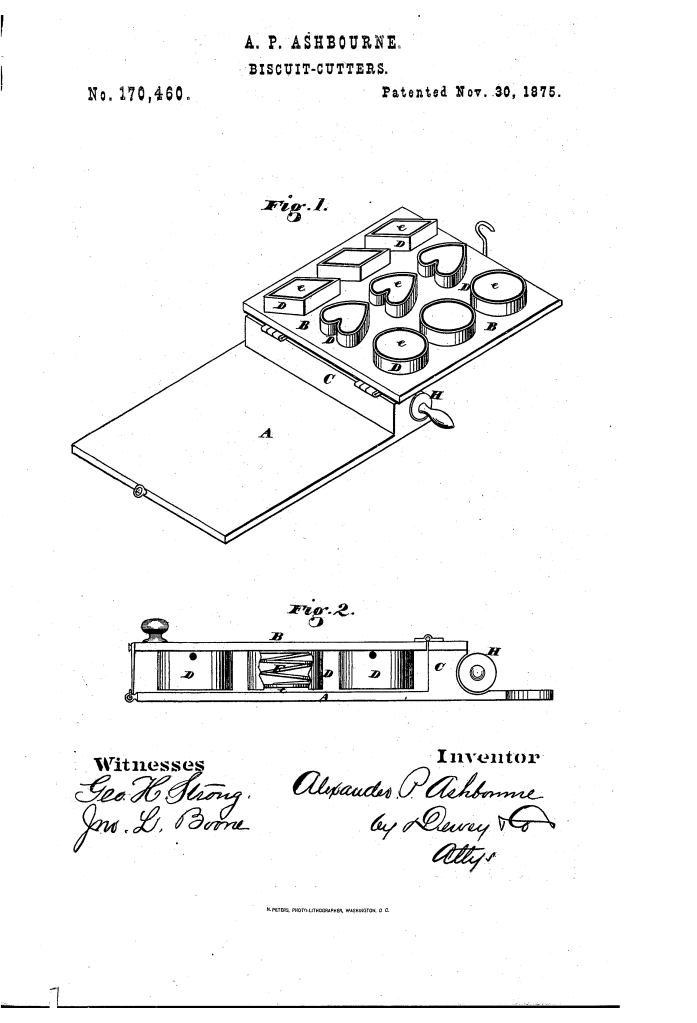

Biscuit-Cutter (Alexander P. Ashbourne, No. 170,460)

The patent describes an Improvement in Biscuit-Cutters invented by Alexander P. Ashbourne of Oakland, California, and patented on November 30, 1875. This novel domestic utensil is designed to speed up the cutting process of dough and ensure automatic, clean release of the cut biscuits.

Invention and Mechanism

The device is a hinged, multi-cutter assembly that performs simultaneous cutting and uses a spring-loaded system for automatic ejection.

- The Cutter Assembly:

- Molding-Board (A): The flat base where the dough (“paste”) is rolled out.

- Cross-Bar (C): Secured to the board (A), it acts as a hinge point for the cover and is shaped with a concave recess to conveniently hold a rolling-pin (H) when not in use.

- Cover or Cutter-Holder (B): A piece hinged to the cross-bar (C), made to hold multiple cutters.

- Cutters (D):Multiple cutters (in metal, of any desired shape) are rigidly secured to the lower side of the cover (B).

- Function: Closing the cover (B) onto the paste performs the cutting of an entire batch of biscuits instantaneously.

- Automatic Ejection Mechanism (Key Innovation):

- Plate (): A plate fitted inside each cutter (D) that nearly fills its outline.

- Spiral Spring (F): A spring positioned beneath each plate (

).

- Operation: When the cutters are pressed down, the plates (

) recede against the tension of the springs (F). When the cover (B) is lifted, the compressed springs (F) immediately force the plates () out again, thereby automatically releasing the cut biscuits onto the board (A).

Historical Significance and the Author

- Pioneering African-American Inventor: Alexander P. Ashbourne’s work focused on improving domestic and food preparation tools in the post-Civil War era. His success in obtaining a U.S. patent demonstrates significant ingenuity and perseverance in a time of limited opportunity.

- Efficiency in Baking: The invention is historically important as an early attempt to mechanize and automate the repetitive process of biscuit cutting. The design allowed a cook to cut an entire sheet of dough in a single action, drastically improving speed and guaranteeing uniform results.

- Early Self-Ejecting Design: The automatic spring-loaded ejection mechanism was a key technical advance, solving the problem of sticky dough damaging the biscuit shape upon removal.

Relation to Current Products

The invention’s core principles are directly incorporated into modern baking tools. The concept of simultaneous, high-volume cutting by pressing multiple cutters at once is the basis for commercial cookie and cracker stamping machines used in industrial bakeries. More prominently, the spring-loaded plate () designed to automatically push the dough out is the exact mechanism found in individual plunger-style biscuit and cookie cutters used in home kitchens today. This enduring design ensures clean, non-stick ejection and preserves the product’s shape.